Suncombe Delivers Advanced Effluent Decontamination System for The Pirbright Institute’s Flagship Brooksby Building

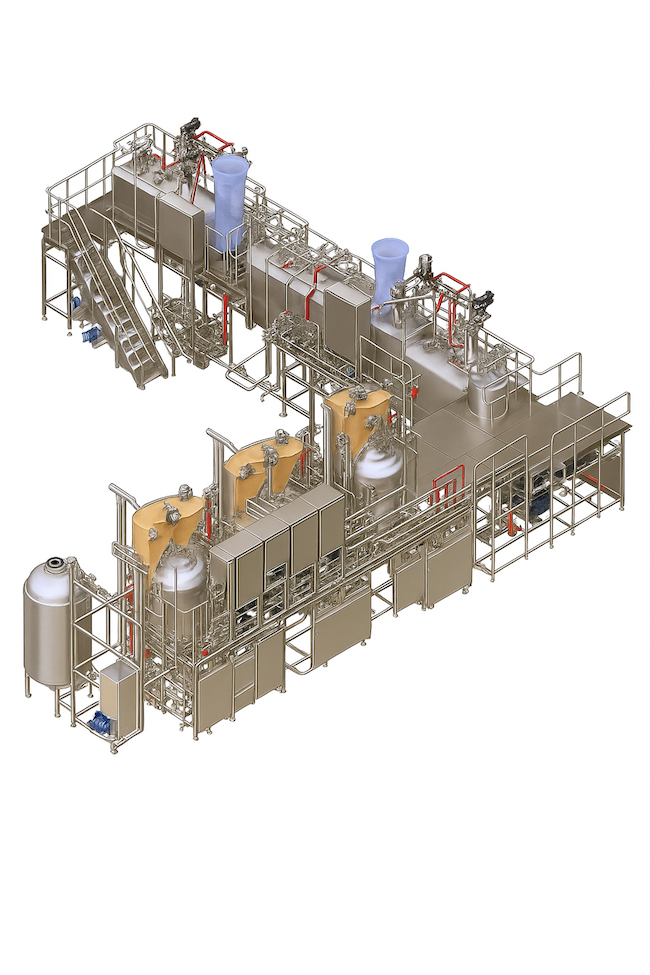

UNITED KINGDOM / AGILITYPR.NEWS / June 24, 2025 / Suncombe - the UK’s longest-serving independent manufacturer of BioWaste Decontamination and Cleaning-In-Place equipment - has successfully completed the design and implementation of a sophisticated Effluent Decontamination System (EDS) for The Pirbright Institute’s new Brooksby Building; a key addition to the UK’s national science infrastructure. This notable project is yet another testament to the company’s expertise in developing critical systems for the most complex, high-containment environments.

Part of The Pirbright Institute - a globally respected research centre focused on controlling viral diseases in livestock and preventing their spread to humans - the new Brooksby Building is a 4,745 square-metre high-biological containment facility designed to support in vivo studies involving high-consequence animal pathogens such as foot-and-mouth disease virus (FMDV). Named after former director of the institute, John Brooksby, the facility also enables research into zoonotic viruses including Rift Valley fever and Japanese encephalitis. Suncombe’s role in the project was to provide the technology needed to safely decontaminate biological waste.

The design and construction of the facility were led by Kier Construction, with Suncombe responsible for delivering the advanced biosafety infrastructure required for Containment Level 4 operation - the highest level of biological containment. Drawing upon decades of experience, the Suncombe team worked closely with project partners from early-stage design reviews through to risk assessments and HAZOPs, resulting in the development and implementation of a system that integrates validated decontamination processes, fully automated control, and system redundancy to ensure uninterrupted safety, reliability and compliance with strict biosafety standards.

“The Brooksby Building project exemplifies Suncombe’s ability to deliver cutting-edge solutions for some of the world’s most challenging and high-stakes environments,” said Steve Overton, Suncombe Operations Director. “This facility required not only an advanced effluent decontamination system but a partner who could collaborate seamlessly with multiple stakeholders, adhere to the highest safety standards, and integrate innovative technologies into a highly regulated environment. I’m proud of how our team rose to this challenge, delivering a system that meets and exceeds expectations.”

The Effluent Decontamination System delivered by Suncombe brings with it a number of key benefits. Designed to ensure complete pathogen inactivation, the system safeguards both personnel and the wider environment from potential exposure. Its fully automated cycles guarantee repeatability and reliability, while the integrated data capture and reporting functions support ongoing compliance with strict biosafety and environmental regulations.

The inclusion of energy-efficient components and energy recovery systems also brings significant sustainability gains, helping to reduce both operational costs and carbon footprint. Plus, with a modular, future-ready design, the system can be easily adapted as the Institute’s research needs evolve over time, offering both immediate performance and long-term flexibility.

For a more detailed look at how the project came together - from early design and hazard analysis through to final validation - the full case study is now available to view. It offers insights into Suncombe’s collaborative approach, technical methodology and how the system is supporting the Pirbright Institute’s ongoing mission to protect animal and human health.

For more information about Suncombe visit https://suncombe.com. To read the full case study, visit: https://suncombe.com/case-study-pirbright-brooksby-building/

Contacts