Suncombe launches IBCSafeConnect to transform safe chemical discharge in line with COSHH regulations

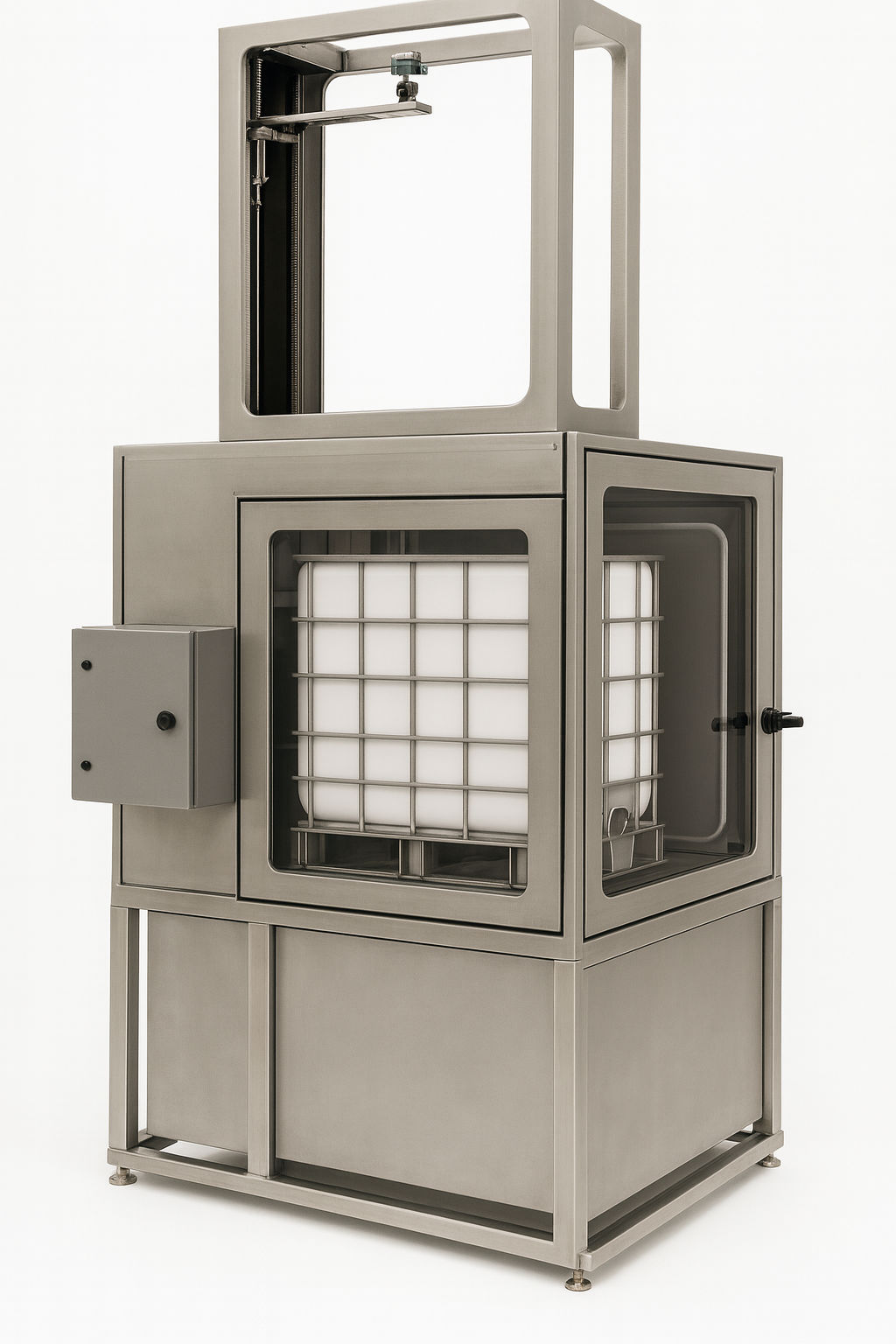

UNITED KINGDOM / AGILITYPR.NEWS / September 04, 2025 / UK-based engineering specialist Suncombe, known for its advanced Cleaning-In-Place (CIP) and biowaste decontamination systems, has unveiled its latest innovation: the IBCSafeConnect. The fully enclosed intermediate bulk container (IBC) discharge unit is designed to automate and safeguard the transfer of chemicals, hazardous and high-value liquids.

By ensuring safe, enclosed chemical dosing in compliance with COSHH, REACH, and HSE regulations it directly works to minimise operator exposure and automation in hazardous material handling.

The innovative new unit’s closed-transfer chemical systems and spill containment eliminate manual handling risks during liquid transfer and supports safe, efficient discharge from 1000-litre IBCs and other transit containers. It is designed for use in a range of environments including pharma and biotech manufacturing, process engineering, food and beverage manufacturing and environmental technology.

The IBCSafeConnect redefines how hazardous and high-value liquids are handled, placing operator safety and process integrity at the forefront. Housed within a sealed, chemical-resistant casing, the system ensures operators are never exposed to dangerous fumes, splashes, or liquid contact during discharge, while its automated lance mechanism eliminates the need for manual input, significantly reducing the risk of accidents or contamination.

Real-time volume monitoring allows users to track chemical levels and prepare for container changeover before issues arise. The system is also fitted with intelligent safety interlocks that prevent operation if the unit is opened, ensuring every discharge is carried out under controlled, secure conditions.

Steve Overton, Technical Director at Suncombe, says, “When designing the IBCSafeConnect, we wanted to strike the right balance between ease of use and uncompromising safety. Our goal was to provide a plug-and-play solution that operators could trust, while still ensuring the unit was easy to use. We’ve achieved this with a system that can be operated with a simple press of a button, enhanced with a strategic set of automatic and enhanced safety features that work behind-the-scenes to maintain the highest levels of protection”.

Suncombe’s focus on finding the right balance in product development goes far beyond performance and purpose, and the IBCSafeConnect reflects a broader commitment to ethical engineering, ensuring solutions are not only effective, but responsible. Aligned with the latest Health & Safety Executive (HSE) and COSHH regulations, the system has been specifically designed to reduce operator exposure, prevent environmental release, and support compliance with UK spill containment and workplace safety guidelines.

110% bunding prevents any potential leaks from reaching the environment, while the compact footprint ensures it can be deployed flexibly across sites without the need for major infrastructure. This focus on environmental responsibility is part of a wider strategy by Suncombe to embed sustainability across all product lines, with the IBCSafeConnect acting as the latest in an extensive series of thoughtfully designed systems that reduce environmental impact through smarter, safer, and more energy-efficient development.

While fully functional as a standalone unit, the IBCSafeConnect has also been engineered to integrate seamlessly into Suncombe’s wider equipment portfolio. It can be paired with existing Cleaning-In-Place (CIP) systems, effluent decontamination units, and both Suncombe and third-party processing equipment to deliver a complete, closed-loop solution. Like all Suncombe systems, it’s designed for long-term performance and regulatory compliance, built to withstand high-use environments while delivering consistent, repeatable results in line with international standards.

For more information about Suncombe visit https://suncombe.com

Contacts